Driven by tightening global environmental regulations and rising consumer awareness of sustainability, a key term in materials science—”plasticity”—is rapidly becoming a crucial focus in the cross-border e-commerce industry. For cross-border e-commerce sellers striving to enhance product competitiveness, optimize supply chain costs, and meet the green demands of the global market, a deep understanding and application of the concept of “plasticity” will bring significant business advantages.

What is “Plasticity” from a cross-border e-commerce perspective?

In the context of cross-border e-commerce, the core meaning of “plasticity” goes beyond the basic material plasticity (physical deformation ability) to emphasize the “circular plasticity” of plastic materials:

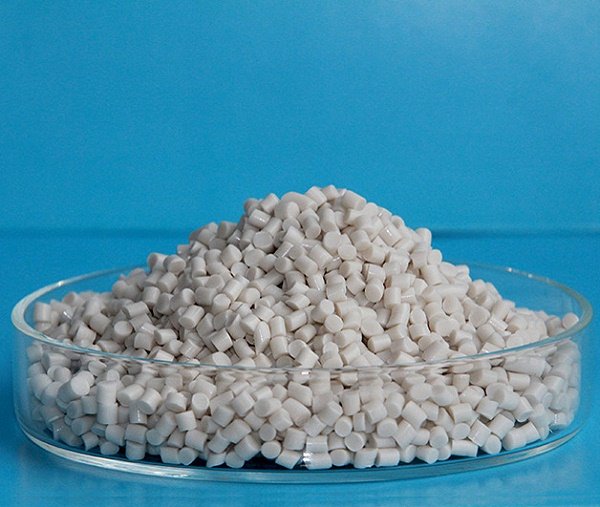

Recyclability: Whether a material can be efficiently recycled and re-entered the production cycle. High plasticity means that the material can be easily sorted, handled, and reprocessed into high-quality recycled materials (such as rPET and rPP).

Design for Recycling: Is the product design (especially the packaging) designed to facilitate recycling? Designs such as single-material, easily separable structures, and reduced composite layers and ink use all enhance the material’s plasticity.

Biobased & Biodegradable Potential: For new bio-based plastics (such as PLA and PHA) or plastics that can be degraded under specific conditions, their “plasticity” at the end of their lifecycle (returning to nature or industrial composting) is also a key factor.

The core value of “Plasticity” for cross-border e-commerce sellers:

Compliance Pass: Several key cross-border e-commerce target markets, such as the EU, the UK, and California, have already introduced or are about to implement strict plastic packaging taxes, Extended Producer Responsibility (EPR) regulations, and the Single-Use Plastics Directive (SUP). Using high-plasticity materials (such as high recycled content, easily recyclable designs, and certified degradable materials) is key to meeting these regulations and avoiding high taxes and penalties.

Brand Image Enhancement and Consumer Favor: Global consumers, especially in mature markets in Europe and the United States, are experiencing a surge in demand for sustainable products. Clearly labeling a product/packaging’s “Plasticity” attribute (e.g., “Made with 50% Recycled Plastic,” “Fully Recyclable,” “Compostable”) can significantly enhance brand image, attract environmentally conscious customers, and increase conversion rates and customer loyalty. Research shows that consumers are willing to pay a premium for sustainable packaging.

Logistics and Cost Optimization:

Lightweighting: High-plasticity materials typically have a better strength-to-weight ratio, helping to achieve lightweight packaging and directly reducing international shipping costs.

Reducing Long-Term Compliance Costs: Preemptively planning for regulatory-compliant materials and designs can avoid future fines, product removals, or additional costs associated with forced material changes due to non-compliance.

Supply Chain Resilience: Focusing on and utilizing recycled materials can help reduce reliance on virgin plastic and enhance supply chain stability.

Product Innovation and Differentiation: Developing products using new, high-plasticity bio-based or high-performance recycled plastics is inherently a key innovation that can help differentiate in the competitive cross-border e-commerce market.

How can cross-border e-commerce sellers embrace the “Plasticity” trend?

Material Traceability and Selection: Proactively communicate with suppliers to understand the composition, recycling levels (e.g., labels 1-7), recycled content, and recyclability certifications (e.g., How2Recycle labels) or compostability certifications (e.g., OK Compost Industrial) for product components and packaging.

Optimize Packaging Design: Implement the “Design for Recycling” philosophy:

Prefer single-material packaging.

Avoid using difficult-to-separate composite materials, PVC, expanded polystyrene (EPS), and other low-plasticity materials.

Reduce the area and types of ink used, using water-based inks.

Remove unnecessary attachments (e.g., plastic handles, excessive decoration).

Clearly mark recycling instructions.

Explore Innovative Materials: Identify and test emerging high-plasticity materials, such as bio-based plastics, recycled ocean plastics, and chemically recycled plastics, to evaluate their performance, cost, and market acceptance.

Transparent Communication: Clearly communicate your efforts to enhance “plasticity” (e.g., recycled content, recyclability, and environmental certifications) in product pages, packaging, and brand storytelling, earning consumer trust with facts and data.

Follow Regulatory Updates: Continuously monitor updates to plastics regulations in key target markets (e.g., the EU PPWR proposal and national EPR requirements) to ensure compliance.